The Future of Apparel Printing!

Multicraft Inc. is The Exclusive Distributor of:

The Future of Apparel Printing!

Available in sizes - 24" and 50"

Game Changing Solution for PET transfer industry

*New solution for PET transfer film:

- You can now print with No Powder DTF™

- in full CMYKW color with the new liquid adhesive.

Multi-Industry Applications

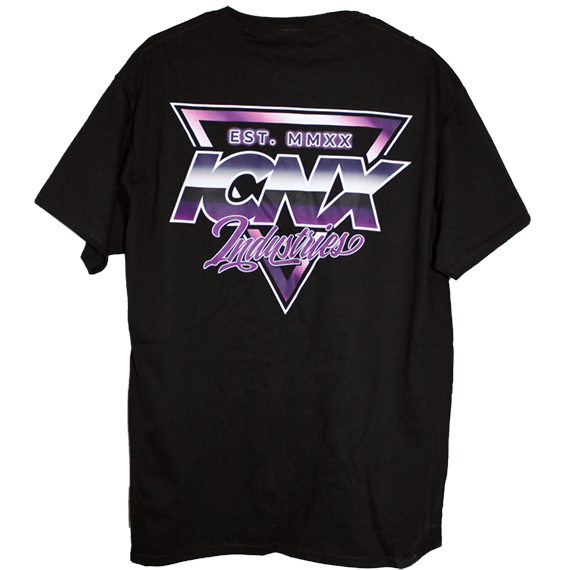

- Apparel: T-shirts, Hoodies, Hats & Beanies

- Sport Jerseys: Football, Baseball & Basketball

- Patches: Leather, Twill, Hemp & Canvas

- Promo Products: Koozies, Tote Bags & Backpacks

Direct to Film No Powder Printers

Direct to film printing is a unique printing technology that involves printing designs onto special films for transfer onto garments. DTF printing is a heat transfer process that has the ability to last as long as traditional silkscreen prints.

DTF Direct to Film transfer printer

Our DTF No Powder Printers offer fast printing, less mess than powder shaker printers, as well as dot for dot adhesion of your print giving you the most out every design, and a softer feel. When running in a high production shop can produce at an incredible pace. Printing transfer machines are the fastest growing eqipment in screen printing and sign shops all over the country.

Another key component of the DTF No Powder Printers is you that will save money when you are running designs for white t shirts, as white ink does not need to be printed unlike powder shaker machines.

DTF Printing Offers Greater Versatility

When printing directly to a textile, your options are limited. DTF gives you much more flexibility, as you can print on a variety of fabrics, including cotton, polyester, rayon, nylon, silk, leather, and more.

Fabric Doesn’t Require Pre-Treatment with DTF Technology

One of the many advantages of DTF printing is that garments do not require any pre-treating in order to accept a transfer. This can streamline your operations and potentially lower your costs. Overall, the DTF printing process is quicker and requires less labor than DTG printing.